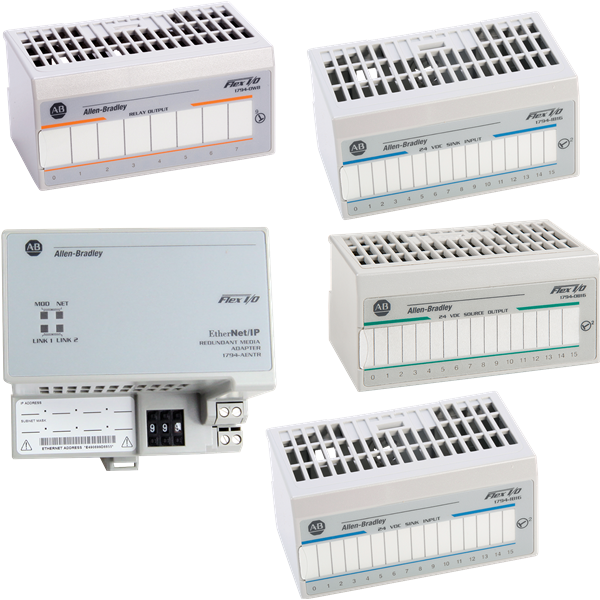

The 1794 FLEX I/O vs FLEX 5000

Allen-Bradley’s 1794 FLEX I/O and the newer FLEX 5000 I/O systems are modular distributed I/O solutions engineered to reduce panel space, simplify wiring, and enhance system flexibility. While 1794 FLEX I/O has been a proven solution in industrial automation for decades, FLEX 5000 I/O builds on this legacy with advanced features, security, and environmental robustness. This guide offers a detailed, categorical comparison to help engineers choose the best fit for their applications.

Environmental Specifications and Safety Certifications

1794 FLEX I/O

-

Operating Temperature: 0°C to 55°C (standard), -20°C to 70°C (XT version)

-

Storage Temperature: -40°C to 85°C

-

Shock Tolerance: 30g (operating), 50g (non-operating)

-

Vibration: 5g RMS @ 10Hz to 500Hz

-

Humidity: 5% to 95% non-condensing

-

Certifications: CE, UL, cUL, C-Tick, ATEX, ODVA, SIL2

FLEX 5000 I/O

-

Operating Temperature: -40°C to 70°C

-

Storage Temperature: -40°C to 85°C

-

Shock Tolerance: 30g (operating and non-operating)

-

Vibration: 5g RMS @ 10Hz to 500Hz

-

Humidity: 5% to 95% non-condensing

-

Certifications: CE, Ex, SIL3, PLe, G3 coating (XT models), Class 1 Div 2, c-UL-us

Conclusion: FLEX 5000 offers broader environmental resilience and higher safety integrity levels.

Network Adapters and Communication

FLEX 5000 I/O Adapters

-

Ethernet/IP support at 10/100/1000 Mbps

-

Models include: 5094-AENTR, 5094-AEN2TR, 5094-AENSFPR, etc.

-

Redundancy: Supports DLR and PRP

-

Security: Explicit & Implicit Protected Modes

-

Time Sync: Supports CIP Sync & PTP

-

Studio 5000 support (v31+)

-

SFP options for copper/fiber networks

FLEX 1794 I/O Adapters

-

Ethernet/IP (10/100 Mbps), ControlNet, DeviceNet

-

Models: 1794-AENTR, 1794-ACN15, 1794-AND, etc.

-

Uses TCP/UDP over CIP

-

Studio 5000 & RSLogix 5000 support (v20+)

Conclusion: FLEX 1794 offers protocol flexibility; FLEX 5000 delivers speed, security, and redundancy.

HART I/O Module Comparison

1794 FLEX I/O

-

Models: 1794-IE8H, 1794-OE8H

-

Protocol: HART V5/V6

-

8 analog I/O per module

-

Supports basic diagnostics and firmware filtering

FLEX 5000 I/O

-

Models: 5094-IF8IH, 5094-OF8IH, XT versions

-

Protocol: HART V5/V6/V7 + HIH (Highly Integrated HART)

-

Channel-isolated analog I/O

-

Advanced diagnostics, readback, and configuration via Studio 5000 (v32.02+)

Conclusion: FLEX 5000 HART modules are more intelligent and support PlantPAx integration.

Specialty and Safety Modules

1794 FLEX I/O

-

Specialty Modules: High-Speed Counter, Frequency, Pulse Counter

-

Safety: Limited, SIL2 certified

FLEX 5000 I/O

-

Specialty Modules: High-Speed Counter

-

Safety: Full suite of SIL3, PLe-rated Safety I/O modules

-

Supports RIUP, Thermocouple, RTD

Conclusion: FLEX 5000 excels in integrated safety and modern specialty modules.

Ease of Integration and Flexibility

1794 FLEX I/O

-

Legacy system with wide install base

-

Interoperable with ControlNet, DeviceNet, EtherNet/IP

-

Flexible network protocol choice

FLEX 5000 I/O

-

Advanced features for modern Ethernet/IP architectures

-

Interchangeable adapters in Studio 5000

-

Better suited for redundant, high-speed applications

Final Verdict Choose 1794 FLEX I/O if you need:

-

Cost-effective solution

-

Multi-protocol support (DeviceNet, ControlNet)

-

Proven legacy compatibility

Choose FLEX 5000 I/O if you need:

-

High-speed, redundant EtherNet/IP networking

-

Enhanced safety and diagnostics

-

Compatibility with modern control platforms like ControlLogix 5580

For tailored recommendations, contact:

PLG Automation

Email: sales@plgautomation.com

Phone: 800-906-9271