12 Common Causes of Servo Motor Failure

Servo motors are essential to modern automation, providing precise motion control in CNC machines, robotics, and manufacturing systems. However, these complex devices are also vulnerable to a range of failure points that can lead to unexpected downtime and costly repairs. Understanding the most common causes of servo motor failure can help businesses plan preventive maintenance and avoid production losses.

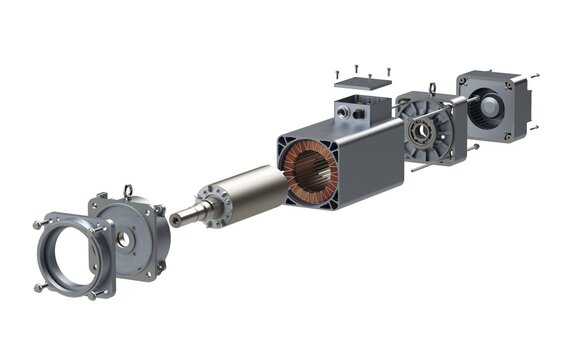

Servo Motor 101

A typical servo motor system includes:

-

Motor: The drive mechanism.

-

Potentiometer: Feedback mechanism for position sensing.

-

Control Circuit: Manages signals between the controller and motor.

Additional components like cables, windings, and bearings also play a crucial role in the motor’s performance.

Early Signs of Failure

Common signs include unusual noises (chatter, shrieks), decreased performance, and overheating. A megohmmeter can be used to detect short or open circuits.

Preventing Servo Motor Failures

A scheduled preventive maintenance plan is the most effective way to avoid failures. Regular inspections, proper setup, and replacement of worn components can prevent unplanned outages.

The 12 Most Common Causes of Servo Motor Failure

1. Contamination

The most frequent cause of failure. Oil, coolant, dust, or debris can enter the motor housing, degrading bearings, windings, and electronics. Regular cleaning and using sealed systems mitigate this risk.

2. Bearing Failure

Characterized by growling or shrieking noises, especially at high speeds. Causes include misalignment, contamination, and natural wear. Vibration sensors can help detect early-stage bearing issues.

3. Brake Failure

Brakes not designed for repeated stopping or e-stops often fail prematurely. Contamination and improper usage are also contributing factors. Use the brake only after the motor fully stops.

4. Bad Windings

Copper coil windings degrade due to age, contamination, or power faults. Vibrations and water exposure also reduce their lifespan. Rewinding or insulation upgrades may be required.

5. Cable Failure

Cables transfer power and signals. Issues such as wear, corrosion, or bending can cause failure. Use high-quality cables and inspect them regularly.

6. Overheating

Environmental heat, ventilation blockages, or overuse can cause internal temperatures to rise. Overheating damages motor components. Operate within temperature specs and use thermal protection if available.

7. Demagnetization of Permanent Magnets

Excessive current, temperature, or mechanical stress can demagnetize permanent magnets, affecting motor torque. Stay within rated limits and inspect magnetism levels during maintenance.

8. Electrostatic Discharge (ESD)

Static discharge can damage internal electronics. Proper grounding and anti-static protocols must be followed during handling and installation.

9. Vibration

Unbalanced loads, improper installation, or external resonance can cause vibration, leading to component fatigue. Ensure proper mounting and alignment.

10. Electronic Component Fatigue

Components wear out due to voltage spikes, temperature cycling, and contamination. Routine inspection and operating within rated conditions can prevent early failure.

11. Mechanical Faults

Misalignment, lack of lubrication, or worn mechanical parts can cause breakdowns. Use quality parts and ensure regular mechanical checks.

12. Loss of Parameters / Setup Issues

Improper setup or loss of stored motor parameters can cause positioning and torque issues. Always back up settings and regularly verify configuration.

Repair or Replace?

When a motor fails, weigh the following:

-

What caused the failure?

-

Do you have a spare?

-

What is the cost of downtime?

-

Is a new motor in stock?

-

Is the failed unit under warranty?

-

Do you have a trusted repair vendor?

If repair costs exceed 50% of replacement and lead time is longer, replacement may be better.

Frequently Asked Questions

What Are the Signs of Servo Motor Failure?

Erratic operation, overheating, noise, or reduced performance.

Can Motor Failures Be Prevented?

Yes via proper setup, compatible components, signal calibration, and regular maintenance.

What Are Some Typical Maintenance Tasks?

Cleaning, inspecting connectors, checking lubrication, and replacing worn parts.

How Can I Troubleshoot a Failing Servo Motor?

Check power and signal cables, inspect components, verify configuration, and use diagnostic tools.

What’s the Lifespan of a Servo Motor?

With proper care, several years depending on use and environment.

Need Help Sourcing Servo Motor Parts?

At PLG Automation, we stock a wide range of replacement servo motors, cables, controllers, and other industrial automation parts. Let our team help you reduce downtime and keep your operations moving.

Contact PLG Automation

Email: sales@plgautomation.com

Phone: 800-906-9271