What is a Real Time Clock (RTC) in a PLC?

I. Introduction A Real-Time Clock (RTC) in a Programmable Logic Controller (PLC) is not like your household digital clock that synchronizes with national time signals. Instead, it is a dedicated component that keeps track of elapsed time within an automation system, allowing tasks to be scheduled or monitored based on specific timing intervals. These internal clocks are crucial for automation tasks that require precision timing and scheduling.

II. Basic Functionality of RTCs At its core, an RTC uses an oscillator circuit to measure time accurately. This circuit records elapsed time from a start point, using interim setpoints to trigger output actions. These time-based setpoints allow the RTC to manage actions such as turning devices on or off, activating alarms, or initiating sequential steps in a process. The time data is stored and maintained internally, even during power loss, often with the aid of a small backup battery.

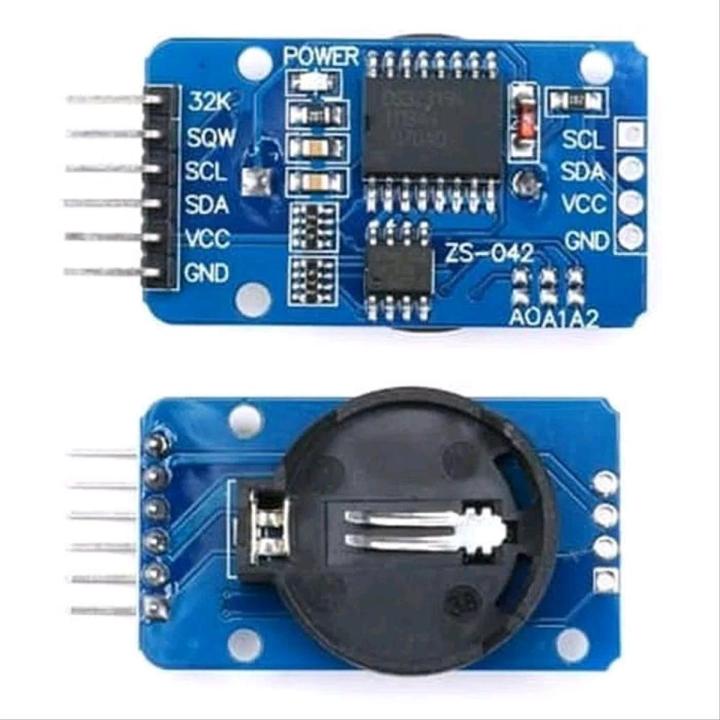

III. Simple RTC Application Example A classic example of RTC use is in school bell automation. A student was tasked with building an automated bell system using an Arduino and an RTC chip (DS1307). The system used simple components:

-

DS1307 RTC chip

-

32.768 kHz crystal oscillator

-

CR2032 battery (for backup power)

-

8-pin IC socket and passive components

By programming specific start and end times, the RTC triggered a relay to activate the bell. This demonstrated how even small-scale projects can implement RTCs for time-based automation, mirroring how PLCs function in more complex systems.

IV. RTC in Industrial Automation In industrial automation, RTCs are a fundamental part of SCADA and PLC systems. They enable:

-

Scheduled activation of motors, pumps, or fans

-

Time-stamped data logging

-

Maintenance scheduling

-

Shift-based process control

The RTC continuously tracks time, allowing automation systems to respond to predefined time triggers with high precision. This functionality is indispensable in applications where time-based control is critical.

V. Case Study: RTC in Hydroponic Systems Hydroponic agriculture requires strict environmental controls for optimal plant growth. PLCs with RTC modules are used to:

-

Activate nutrient pumps at specific times

-

Control lighting and fans based on a time schedule

-

Drain and refill water reservoirs

-

Adjust pH and nutrient levels on a timed basis

Sensors feed real-time data to the PLC, and based on that data and RTC schedules, automated actions are performed. This not only ensures better yield but also minimizes waste of resources like water and fertilizer.

VI. Time-Based Logic and Relay Triggers RTCs are often programmed to trigger relay outputs at specific setpoints. These relays then control connected hardware. The timing logic may be set:

-

Daily (e.g., every day at 6 AM)

-

Hourly (e.g., every hour on the hour)

-

Event-driven (e.g., after a temperature threshold is met for 15 minutes)

This time-driven control allows systems to function without constant human intervention, improving efficiency and reliability.

VII. Conclusion A Real-Time Clock in a PLC is a powerful, often underappreciated component that enables precise, reliable control in time-sensitive applications. It differs from everyday clocks by focusing on elapsed time and programmable triggers rather than simply showing the current time. From small school projects to complex hydroponic farms and industrial automation networks, RTCs play a central role in turning logic into action on time, every time.

Contact PLG Automation

Email: sales@plgautomation.com

Phone: 800-906-9271