Digital Sensors vs. Analog Sensors: Understanding the Key Differences

In industrial automation, sensors are the foundation of reliable machine control and monitoring. From temperature and pressure to positioning and speed, sensors feed vital data into control systems helping manufacturers boost efficiency, precision, and uptime.

Two primary types of sensors dominate the landscape: analog sensors and digital sensors. While they often serve similar purposes, the way they collect, process, and transmit data is fundamentally different.

Understanding the difference between analog and digital sensors is key to choosing the right solution for your application—and maximizing your system’s performance.

What Are Analog Sensors?

Analog sensors detect physical properties and produce a continuous output signal, usually as a voltage or current that changes in proportion to the measured parameter.

How They Work:

Analog sensors convert real-world phenomena ( temperature, pressure) into electrical signals that represent a full range of values. There are no discrete steps just smooth, uninterrupted measurement.

Common Analog Sensor Applications:

-

Temperature sensing – Thermocouples, RTDs

-

Pressure monitoring – Strain gauge-based pressure sensors

-

Speed measurement – Tachometers, analog rotary encoders

-

Flow monitoring – Differential pressure flow sensors

Advantages:

-

Continuous, high-resolution data

-

No quantization limits – Infinite values within range

-

Quick response time – Ideal for real-time control

Limitations:

-

Signal degradation – Susceptible to electrical noise and interference

-

Requires conversion – Needs analog-to-digital converters (ADCs) for PLC integration

What Are Digital Sensors?

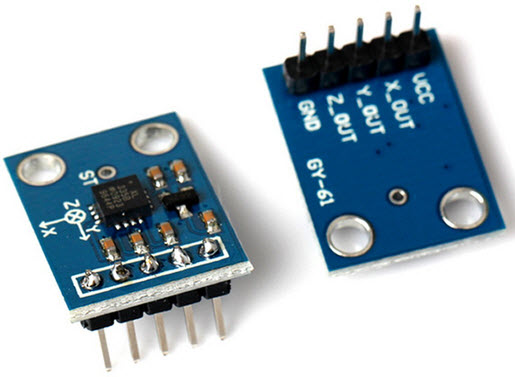

Digital sensors integrate internal processing to convert analog input into a discrete digital signal—often binary (1 or 0), or multi-bit in smart sensors.

How They Work:

Digital sensors use built-in microcontrollers to process data and output digital signals. This makes them plug-and-play for modern control systems like PLCs, SCADA, or IoT platforms.

Common Digital Sensor Applications:

-

Proximity detection – Inductive or capacitive sensors

-

Object counting – Photoelectric or ultrasonic sensors

-

Positioning and alignment – Optical encoders

-

Smart manufacturing – IoT-enabled sensors with diagnostics

Advantages:

-

Resistant to noise – Reliable even in electrically noisy environments

-

Direct integration – Seamless communication with digital systems

-

Self-monitoring – Often includes built-in diagnostics or auto-calibration

-

Efficient long-distance transmission – No signal loss over extended wiring

Limitations:

-

Finite resolution – Depends on bit depth of the internal processor

-

Higher cost – Upfront investment can be greater than analog alternatives

-

Step-based readings – Not ideal for detecting subtle, continuous changes

Analog vs. Digital Sensors: Side-by-Side Comparison

| Feature | Analog Sensors | Digital Sensors |

|---|---|---|

| Output Signal | Continuous (variable voltage or current) | Discrete (binary or digital format) |

| Noise Sensitivity | High | Low |

| System Integration | Requires ADC for digital systems | Directly compatible with PLCs and IoT devices |

| Resolution | Infinite within range | Limited by bit conversion |

| Reliability | May degrade over distance or interference | Stable and consistent |

| Cost | Lower initial cost | Higher upfront investment |

| Best Use Case | Smooth, gradual measurements | Real-time automation and diagnostics |

Which Sensor Type Is Right for Your System?

Choosing between analog and digital sensors depends on your operational priorities:

Choose Analog Sensors if:

-

You need continuous, fine-grained measurements

-

Your application tolerates noise-sensitive wiring

-

You're working with legacy control systems

Choose Digital Sensors if:

-

You want easy integration with PLCs or IoT platforms

-

You require noise immunity in an industrial setting

-

You’re looking for self-diagnostics and lower maintenance

Pro Tip: Many advanced systems combine both analog and digital sensors to capture detailed measurements and simplify control system integration.

Conclusion

Both analog and digital sensors play critical roles in modern automation. Analog sensors shine in applications requiring smooth, high-resolution data. Digital sensors, on the other hand, excel in reliability, smart connectivity, and integration with today’s PLCs and edge devices.

By understanding the strengths and trade-offs of each, you can select the sensor technology that best supports your system’s accuracy, uptime, and future scalability.

Need Help Selecting the Right Sensor?

PLG Automation supplies both analog and digital sensor technologies for industrial control applications. We can assist with compatibility, system design, and fast shipping on trusted brands.

📧 Email: sales@plgautomation.com

📞 Phone: 800-906-9271