Omron CPM1 vs CPM2: A Comparative Analysis

Omron's CPM1 and CPM2 series are foundational programmable logic controllers (PLCs) used in a broad range of industrial automation applications. While both share key features in logic control and reliability, they serve distinct roles depending on the complexity and scalability of the system in which they are deployed. This guide provides an in-depth comparison of their capabilities, specifications, and use cases.

Technical Specifications

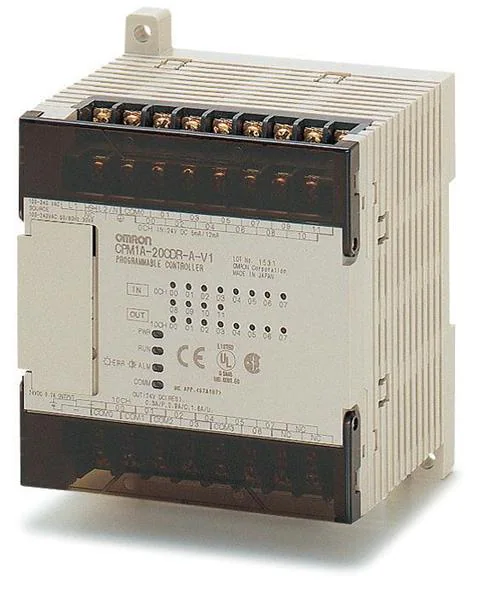

CPM1: Compact and Cost-Effective

-

Voltage Range (AC): 100–240 VAC, 50/60 Hz (operational: 85–264 VAC)

-

Voltage Range (DC): 24 VDC (operational: 20.4–26.4 VDC)

-

Power Consumption: Up to 30 VA (AC), with 30A inrush current

-

Operating Temp: 0°C to 55°C

-

Key Benefit: Ideal for compact and budget-sensitive control applications

CPM2: Robust and Scalable

-

Voltage Range (AC): 100–240 VAC (85–264 VAC operational)

-

Voltage Range (DC): 24 VDC

-

Power Consumption: 60 VA (AC), 20W (DC), with 60A inrush current

-

Operating Temp: 0°C to 55°C; storage: -20°C to 75°C

-

Humidity: 10% to 90% RH

-

Key Benefit: Built for more expansive applications with higher I/O and performance needs

I/O Control Systems

Programming and Instructions

-

Language: Ladder Logic for both

-

Execution Method: Stored program with cyclic scan and immediate refresh

-

CPM1: 14 basic + 79 special instructions = 139 total

-

CPM2: 14 basic + 105 special instructions = 185 total

-

Execution Times (CPM2): LD = 0.64 µs; MOV = 7.8 µs

Capacity

-

CPM1: 2,048 words program memory; up to 100 I/O points (with expansion)

-

CPM2: 4,096 words program memory; up to 120 I/O points (with expansion)

Memory & Diagnostics

-

Memory Backup:

-

CPM1: Flash memory + battery backup

-

CPM2: Enhanced 5-year battery backup

-

-

Diagnostics:

-

CPM1: Self-diagnostics included

-

CPM2: Expanded diagnostics including I/O bus error detection

-

Communication Capabilities

CPM1

-

Protocols: Host Link

-

Topologies: 1:1 and 1:n (via RS-422)

-

Adapter: Requires CPM1-CIF01 for RS-232 communication

CPM2

-

Protocols: Host Link, NT Link (1:1)

-

Flexibility: Supports RS-232, RS-422/485

-

Adapters: Enhanced support for NT-Terminals and multiple topologies

Input Circuit Design

CPM1 Input Circuit

-

Voltage: 24 VDC (+10% / -15%)

-

Impedance: 2 kΩ – 4.7 kΩ

-

Current Draw: 5 – 12 mA

-

Delays: 1 – 128 ms (ON/OFF)

CPM2 Input Circuit

-

Voltage: 24 VDC (+10% / -15%)

-

Impedance: 2.7 – 4.7 kΩ (more granular)

-

Current Draw: 5 – 8 mA

-

Delays: 1 – 80 ms (default: 10 ms)

-

High-Speed Input: Up to 20 kHz

Relay Output Circuits

CPM1 Relay Outputs

-

Capacity: 2A @ 250VAC / 24VDC

-

Endurance:

-

Electrical: 100k – 150k operations

-

Mechanical: Up to 20M operations

-

-

Switching Delay: 15 ms (ON/OFF)

CPM2 Relay Outputs

-

Same Ratings as CPM1, with improved minimum switching capacity (10 mA @ 5 VDC)

Expansion and Connectivity

CPM1-DRT21: DeviceNet Slave

-

I/O Mapping: 32 inputs and 32 outputs

-

Addressing: DIP switch configurable

CPM2-SRT21: CompoBus/S Slave

-

I/O Mapping: 8 inputs and 8 outputs

-

Flexibility: Optimized for decentralized control

Summary and Conclusion

The Omron CPM1 series is best suited for smaller, cost-sensitive applications requiring a compact footprint and essential control functions. Its straightforward configuration and reliable performance make it a solid choice for foundational automation.

In contrast, the CPM2 series is built for scalability, offering expanded instruction sets, enhanced memory, better diagnostics, and advanced communication capabilities. It is ideal for more demanding industrial environments that require greater flexibility and integration.

Whether you're building a simple machine control system or implementing a complex automation network, the decision between CPM1 and CPM2 should be guided by the required I/O capacity, processing power, communication needs, and expansion potential.

Contact PLG Automation today:

Email: sales@plgautomation.com

Phone: 800-906-9271